Whey from cheese production and other agricultural waste can be a valuable raw material for new biodegradable plastic. A European research project

Whey from cheese production and other agricultural waste can be a valuable raw material for new biodegradable plastic. A European research project is working on using these by-products in laminated cardboard for food packaging.

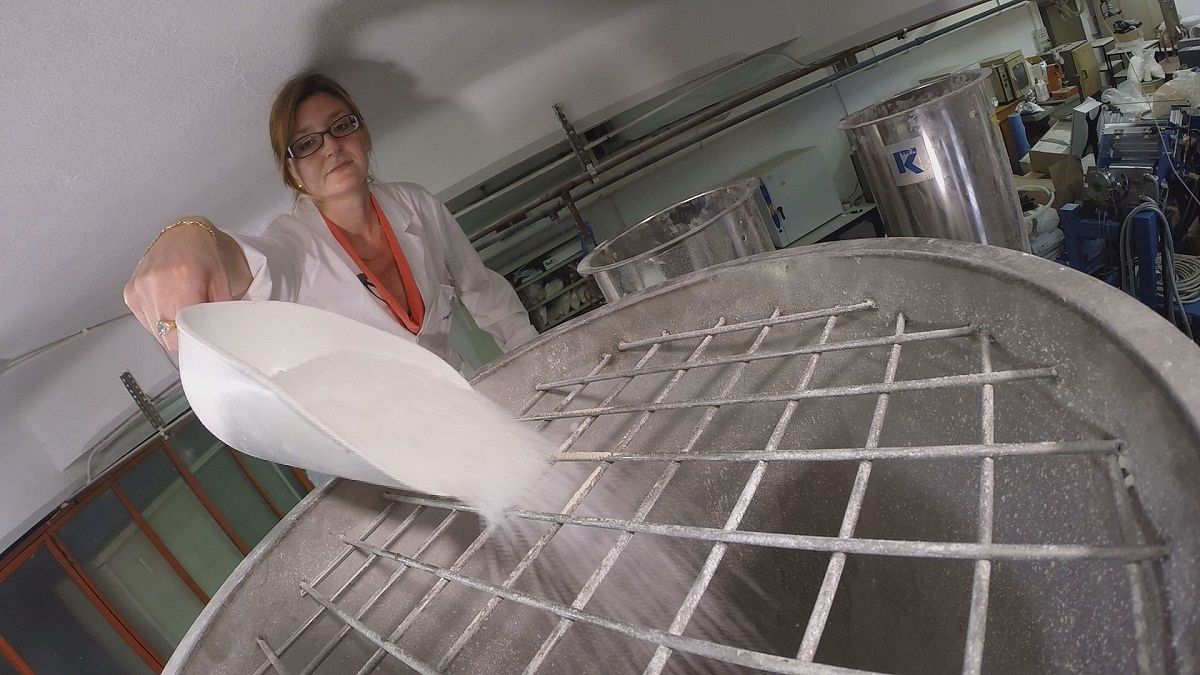

Futuris visited a plant where the research is being carried out. Maria Beatrice Coltelli, a researcher in material science at DICI-UNIPI in the University of Pisa explained her role in the process: “The granules are used to obtain a film which is inserted into a part of a multilayer material that also includes cardboard and aluminium.”

Industrial scale

The aim of the research is to develop this method on an industrial scale. A factory in Mimizan, France produces paper-based laminates combining different materials. Each layer plays its part in protecting the contents of the packaging. Plastics that offer a large range of barrier properties, such as polyethylene, were first produced over 50 years ago.

“This new material is made from waste, proteins that are byproducts of agriculture,” said Anne Kaschke, a packaging engineer with Gascogne Emballage. “It’s sustainable and completely renewable, unlike fossil resources, and that’s why we think it can be a viable alternative to plastic film in the future.”

With more research and development, the new bioplastic can be further improved. It can be made thinner and easier to use in production, but with the same barrier properties and mechanical strength, as Elodie Bugnicourt, Bio-Board project coordinator explained: “It’s impossible to to break with your hands. There are some properties that we’re still working on improving, for example everything to do with the industrial process, processing where we need to increase the speed of production and improve the convertibility of materials to enable them to pass through machines like this one.”

Recycling advantages

Another big advantage of the new bioplastic is that it simplifies recycling. Individual materials in the laminated cardboard can be separated more easily than those in normal laminates and can be recovered more efficiently.

“We have tested how simple it is to separate the layers – it’s important to recover the polyethylene, the aluminium and most of all the fibres, which are very useful in producing recycled cardboard,” said Marco Buchignani, Head of Paper Quality Control at Lucense in Italy.

With good mechanical properties, green origins and better recyclability new bioplastics are destined to become part of daily life.