This is the story of how a small European Union family business has grown to become a global game changer in the ultracompetitive sector of clean steel. A technological challenge… made in Europe.

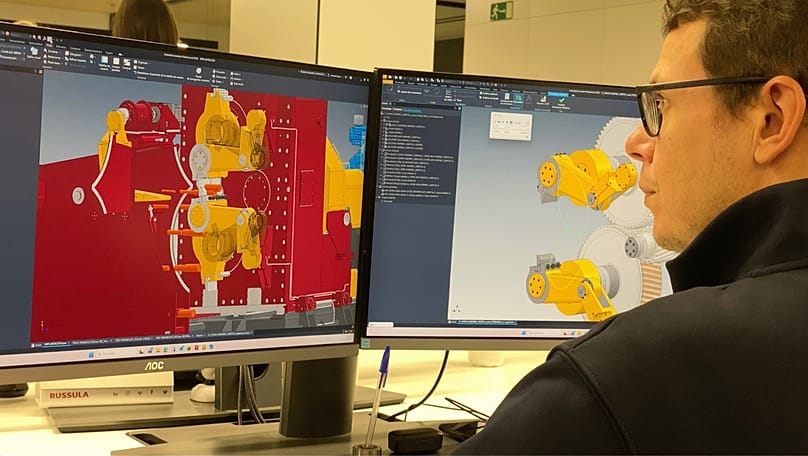

Now a global competitor, the Russula Group has designed 130 steel factories and industrial waste water treatment plants in 35 countries worldwide.

The European steel sector is their next big target. The managers estimate that the European Union is short by roughly 10 million tons of steel each year. They think Europe has now the knowhow to lead the way in the production of clean steel, in both profitable and sustainable ways.

“This reindustrialization in the 21st century is absolutely sustainable because the technology we Europeans have developed in recent years is completely environmentally friendly”, says Eva Maneior, CEO at Russula Group. “There's no excuse. And is it profitable? Very profitable.”

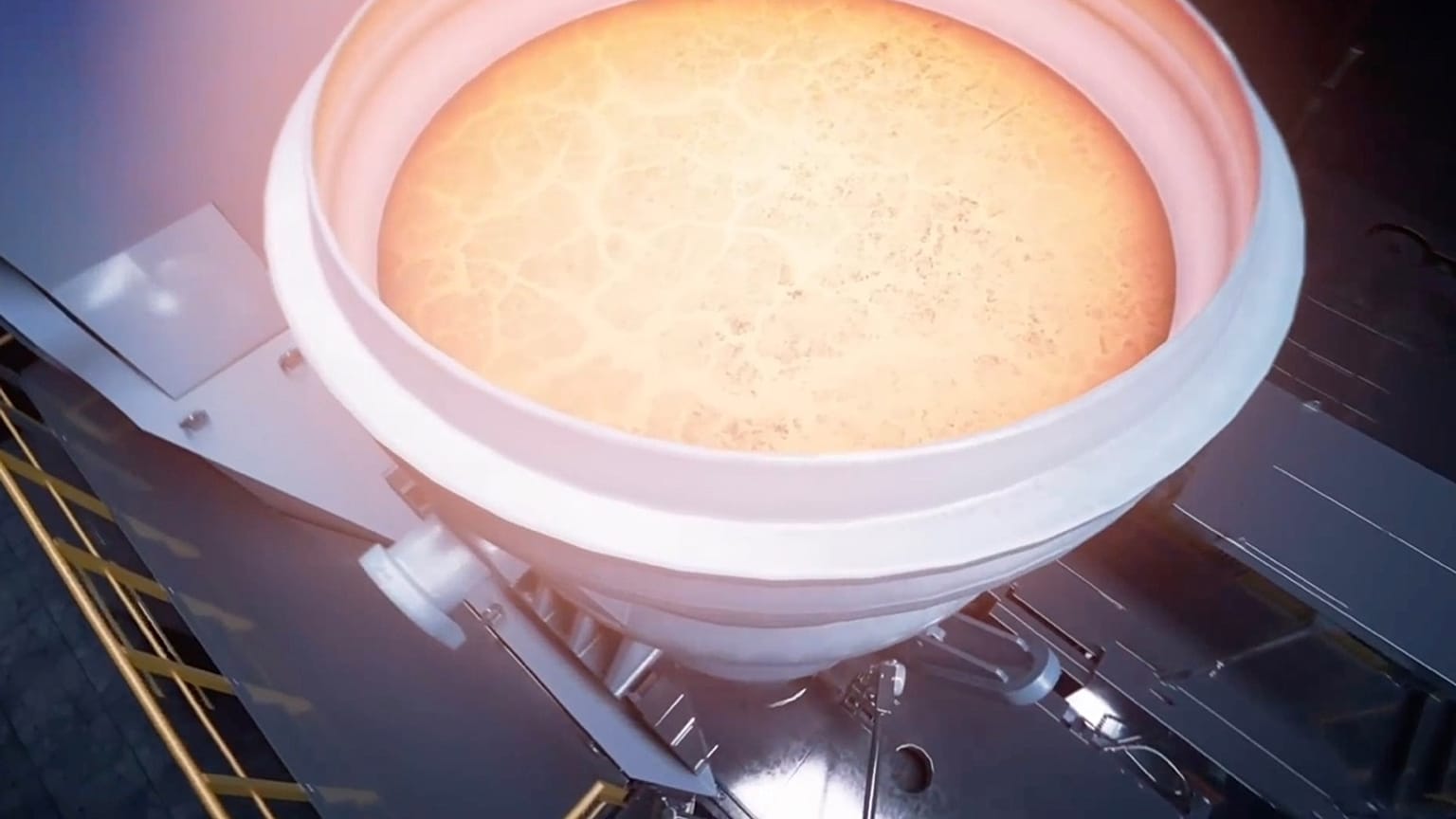

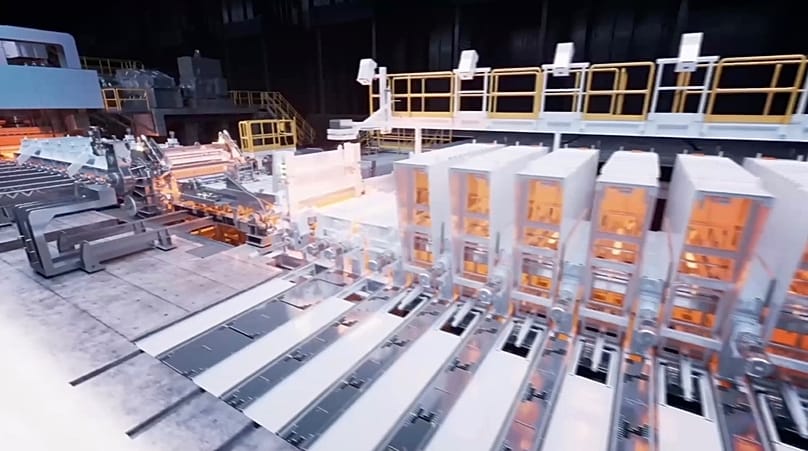

To show the example, the company will soon be starting the construction of its own new ultraeficient factory of clean steel in Central Spain. An initial investment of 1.6 billion euros. The main raw material will be ferrous scrap. The factory will run on renewable energy, including green hydrogen. Managers claim steel manufactured here will emit 98% less emissions of CO2 than in ordinary steel factories.

“Today we consider that the steel industry is responsible for almost 10% of the total greenhouse emissions in the world. So we understand that it is extremely necessary to begin the transition and use these new technologies that can save millions of tons of CO2”, says Fernando Pessanha, Chief Strategy Officer at Hydnum Steel. “For instance, in our facility, the amounts of CO2 we are avoiding equals the full city of full emissions of all the cars in the city like Madrid. So it's a massive amount and it's paramount to push the green transition.”

They hope to produce 1.6 million tons of flat roll steel products in a first phase, and to double the production consequently. Managers claim the factory will create some 1,000 direct jobs when fully operational, with thousands more indirect jobs on the pipeline.

Sustainable Innovation will be key to ensure a competitive future for the European steel industry, managers here conclude.

“Sectors like automotive, infrastructure, and renewable energy have already committed to decarbonization, and for this, they need the entire value chain, all their production processes, to be decarbonized”, says Daniel Sánchez, Chief Operating Officer at Russula Group. “Steel plays a very important role, and it all comes down to decarbonization along its supply chain”

Engineers make up 60% of the company´s staff. They are giving the last finishing details to the new steel factory plant, while working on many other projects worldwide.