French researchers are turning discarded oyster shells into eco-friendly concrete with significantly lower CO₂ emissions. Currently being tested along the French Atlantic coast, this material could replace scarce sand and gravel while supporting marine life.

Oyster farming, a centuries-old tradition along France’s coastlines, faces a hidden challenge. For every succulent oyster that reaches our plates, another one doesn’t survive. An empty shell remains – creating mountains of waste that farmers must manage. With mortality rates reaching 50–90% in some harvests, these discarded shells represent both an environmental burden and an untapped resource.

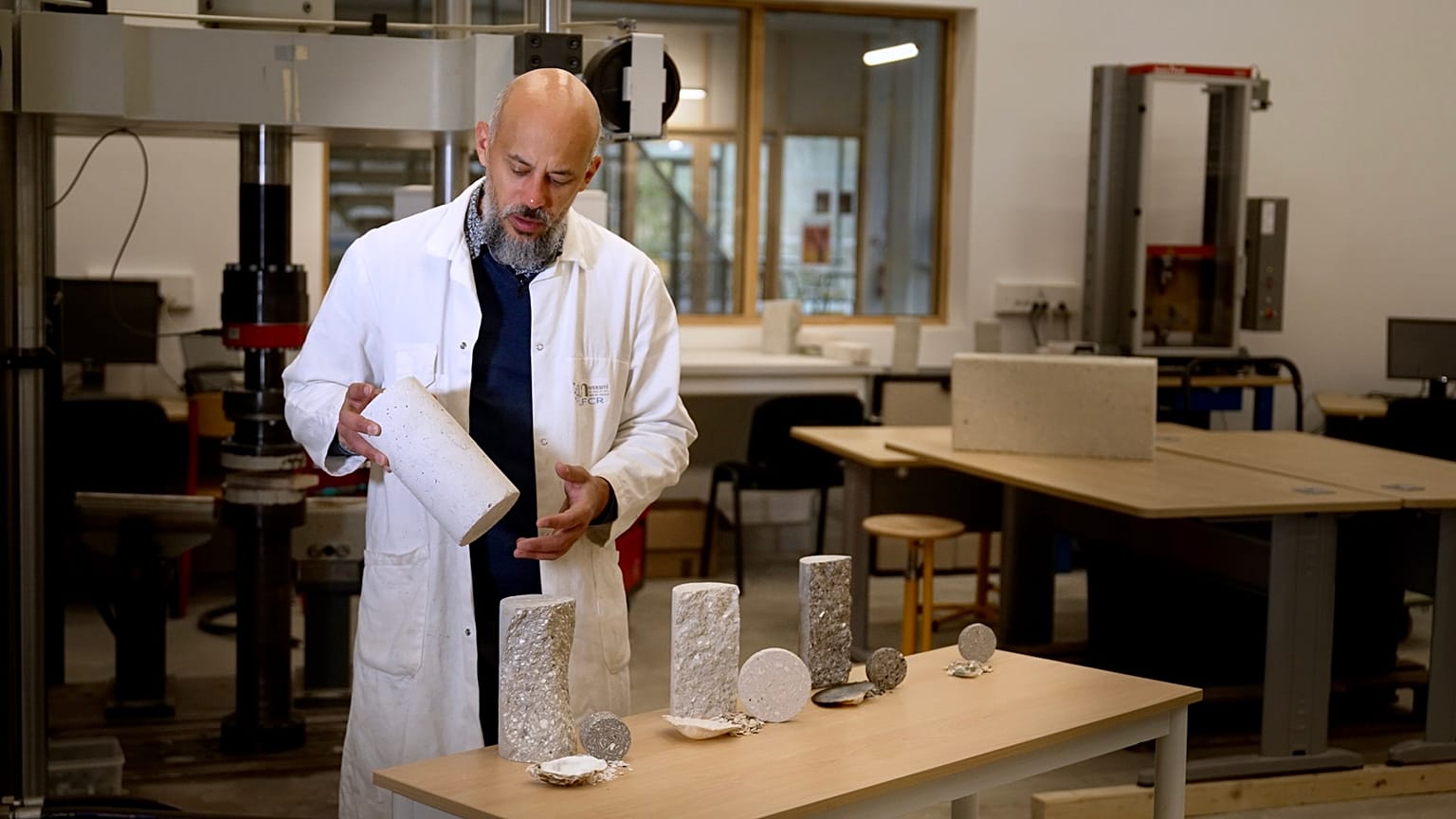

Professor David Grégoire and his research team at the University of Pau and the Pays de l’Adour are transforming this marine waste into what they believe is a construction material of the future.

“If we look at coastlines around the world, we can see seashells being used to make concrete in places like Senegal, Morocco, and many coastal regions,” explains Professor Grégoire. “Shells have long served as raw materials in traditional construction.”

What sets his research apart, however, is that he completely replaces the usual sand and gravel with crushed oyster shells – a truly non-conventional approach in modern construction.

The science behind this innovation is surprisingly simple. Oyster shells, bio-mineralised by molluscs, are essentially natural limestone composed of calcium carbonate. This makes them chemically similar to traditional building materials, but with unique advantages.

This shell-based concrete can address multiple environmental challenges simultaneously – starting with the decline of quarries. As Professor Grégoire points out, “We’re conserving resources since we don’t need conventional sand, which is becoming increasingly scarce worldwide.”

The benefits extend beyond resource conservation. By combining these shells with low-carbon cements, the resulting concrete greatly reduces CO₂ emissions compared to conventional production methods.

Another potential advantage is currently being tested. “Our material offers better bio-compatibility,” notes Grégoire, making it ideal for marine applications like artificial reefs that support ecosystem regeneration.

The innovation is already proving itself in real-world applications. Visitors to the Dune du Pilat, Europe’s tallest sand dune, now walk on pathways made from this oyster-based concrete, which has withstood years of heavy foot traffic.

This work isn’t just solving a waste problem – it’s helping create a circular model where one industry’s rubbish become another’s building blocks.