How can we see the invisible?

In highly unusual places, an army of small portable devices is already detecting what can’t be seen by the naked eye.

Such state-of-the art technology is showing that the future can, to some extent, be predicted and prevented, with no need for a crystal ball.

Asbestos is a silent, invisible killer that claims thousands of lives in Europe each year.

Researchers have installed a small box and a computer at a construction site in England. Its aim: to detect asbestos and prevent unnecessary deaths.

Physicist Chris Stopford from the University of Hertfordshire explained more about the prototype asbestos detector, known as “ALERT”:

“It is currently plugged into a laptop, which does all the data recording and manipulation. The screen is displaying the scattering pattern from every particle that goes through the instrument. Here it is quite dusty, but it is random dust rather than being fibres, so we are not seeing any asbestos fibres at all. The device works by bringing air into this inlet and into a chamber where a particle is illuminated first by one laser and the scattering pattern from that is captured and is then exposed to a magnetic field, which preferentially rotates asbestos fibres against non-asbestos fibres.”

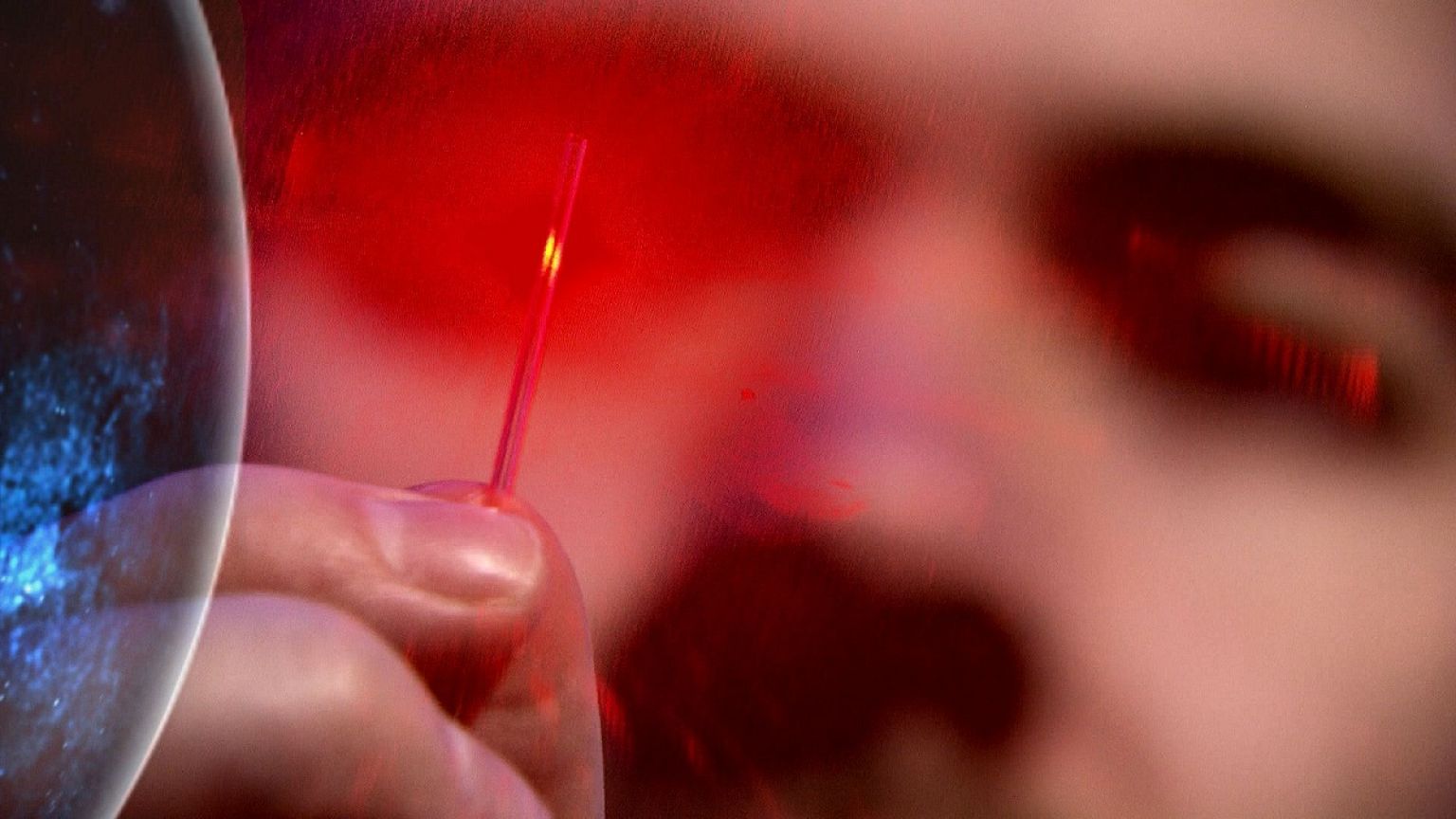

When exposed to magnetic fields, asbestos fibres react in a very particular way: they rotate. Researchers matched that property with laser science to develop their device.

“This fibre is about 1,000 times larger than an asbestos fibre,” continues Stopford. “But when when we introduce it to a laser beam, it illuminates itself in exactly the same way as an asbestos fibre would, creating a very similar scattering pattern”

Their work also involves dealing with real asbestos fibres. Such risky research techniques are now possible thanks to huge technological advances and lower costs:

“The primary reason this has not been done before now is funding issues. Lasers were very expensive. Computer power was also very expensive,” Stopford remarks.

“So researchers could not make something cheap and portable that people could take out into the field and use. Now lasers have come down in price; also computer power has come down in price”.

Confident that their prototype works, researchers are moving on with the project.

“The next step from this prototype is to remove the laptop, to have some internal electronics doing the data analysis,” explains Stopford.

“After that, we would like to increase the air flow, so that we’ll look at more particles per second and we get analysed a larger proportion of air in a room through the instrument more quickly”.

ALERT project coordinator, Alan Archer, would like to develop the system further.

“We have already in mind a hand-held version of ALERT. We feel that we need to have a unit that is worn,” he explains.

“So that when a contract is drilling and hammering, the system breathes the same air that he breathes. That would give a vibration and an audio alarm. It only takes one fibre to be inhaled to do substantial damage in someone´s body, so you want to avoid, wherever possible to have contact with airborne asbestos”.

But sometimes seeing what’s invisible can also be a quest to improve wine quality, at grass roots level.

At one vineyard in Portugal, a different type of grape harvest is underway.

Researchers are testing a small device called “winepen,” which can, quite literally, write down what is deep inside the grapes.

Agronomist Teresa Manso thinks the device is very useful.

“It allows us to measure the ripeness of grapes on site and in a non-destructive way. We can very quickly measure the levels of sugar, acidity and polyphenols inside the grapes,” she said, adding “The device has an integrated GPS system, so we can walk all the way through the vineyard making different measurements. We can then manage the vineyard taking into account this data.”

The device works by measuring the natural response of grapes and their molecules to light.

Data provided by the pen is then uploaded into computers, linked to mathematical models and finally translated into maps that can also be read on portable devices.

Joao Miguel Encarnacao, a molecular biologist, talked us through the benefits of the device, referring to one particular vineyard to support his explanation:

“So this is a map that shows the distribution of sugar in the grapes at one particular vineyard. The scale goes from green to red. Regions in green show low sugar content inside the grapes; regions in red show the areas where grapes have the highest concentration of sugar.

“In this particular case, we see that in one region there is a lower sugar concentration, so winegrowers can make a more informed decision to produce a certain type of wine. But there is also a region in the vineyard with a much higher sugar concentration, where winegrowers can decide to produce another type of wine, with more alcohol; a more vigorous and structured wine.”

Winemaker Fabiano Varandas dos Santos welcomes the idea with open arms.

“This way we don’t have to spend our time taking grape samples from each plant, then taking them to the laboratory for analysis, and having to then wait for the results to come back to us,” he said. “It is a really slow, painstaking process that we won’t have to follow anymore, thanks to this tool. We can have the results in real-time, and we can plan our grape harvesting activities from one day to the next.”

The device was developed during a European Union research project. Scientists now plan to improve the technology under the so called “Horizon 2020” framework programme; the new financial tool for the advancement of research and innovation in Europe.

Researchers, such as agronomist Luís Miguel Fernandes from the Agri-Ciência/PREMIVM project, are not short of ideas.

“The device has to be more ergonomic; in the future we would like it to be better adapted as a hand-held instrument,” suggests Fernandes.

“And we also have to keep working on improving the sensor. It is an optical sensor, and the light will often interfere with the readings. So we have to make sure that the sensor is well-focused on the grapes it has to measure. We need to try to minimise the light’s interference in the readings we take with it.”

At an institute in Germany, baker Reiner Stolzenberger is taking a hands-on approach. He is cooking traditional bread with cereals, some of which have been imported from India and China.

Although they have been given labels certifying that they comply with strict EU legislation on pesticides, bakers often still have some doubts about the quality of the cereals.

“Our suppliers guarantee that the imported cereal is pesticide free and we are sure that, in 99 percent of cases, this is true, and the quality is good,” Stolzenberger explains.

“But of course we would like to be 100 percent sure. That is why it is important. And we would like to be able to verify this by ourselves.”

In order to do that, researchers have developed a device designed to quickly detect some pesticides in cereals. The prototype was built upon research done by Greek scientists and it is based on complex biological and chemical processes.

But its use is very simple, according to scientists such as Foodscan food chemist, János-István Petrusán.

“The system registers the reaction between antibodies and living cells,” he clarifies. “Then this data is forwarded as an electronic signal to the machine where it is processed. The result will show whether or not the sample is contaminated.

“The system is developped with small and medium enterprises in mind. It is important that they have easy access to it. No great skill is needed to use the system, in fact any employee of such a business can use it after a short training course.”

The samples used in the test are identified as pesticide-free: the baker can indeed bake his bread.

He says he would be happy to invest in a device like this, and he sees other invisible substances he’d also like to keep an eye on:

“It is very important to improve this technology so that we can verify if other toxic products are in the raw material we make food with: products such as heavy metals or other toxic products, so that we can sell healthy and clean produce to our customers”.

Researchers conclude, therefore, that customers and citizens have everything to gain from their efforts to see the invisible.

Find out more:

premivm.eu

asbestos-alert.com

foodscan.net

www.ec.europa/research/horizon2020