Nicolai Peitersen gives us his take on digital fabrication and how it could revolutionise fashion.

Nicolai Peitersen is co-founder of Wikifactory and the author of The Ethical Economy. Here he gives us his take on the digital future of fashion.

ADVERTISEMENT

ADVERTISEMENT

ADVERTISEMENT

ADVERTISEMENT

The fast fashion industry has been under the microscope for years. The rapid and cheap production of clothing has a huge negative impact on the environment. Increased pollution, litres of wastewater and waste from materials are difficult and sometimes impossible to recycle. But there are also grave questions around the treatment of labour factory workers.

With Fashion Revolution Week well underway, what better time to reflect over how far the industry has come but also how much is yet to tackle.

Eight years ago, when the factory in Rana Plaza collapsed, tragically taking the lives of more than 1,000 workers, the industry experienced a wake-up call. People started to give much more thought as to where their clothes were coming from, who was making them, in what quantities and in what conditions. Many campaigns and initiatives were born out of the aftermath, including Fashion Revolution Week, which works hard with people all over the world to demand a fairer and safer clothing industry.

Despite all these awareness campaigns, fast fashion has a long way to go.

It is forecast that the global fast fashion industry will be worth 43 billion US dollars in 2029 (compared to 36 billion in 2019), and increasing demand could add more pressure on cheap labour. As a result, many big brands have come up with new processes to change or improve their production models, to make their processes and businesses sustainable.

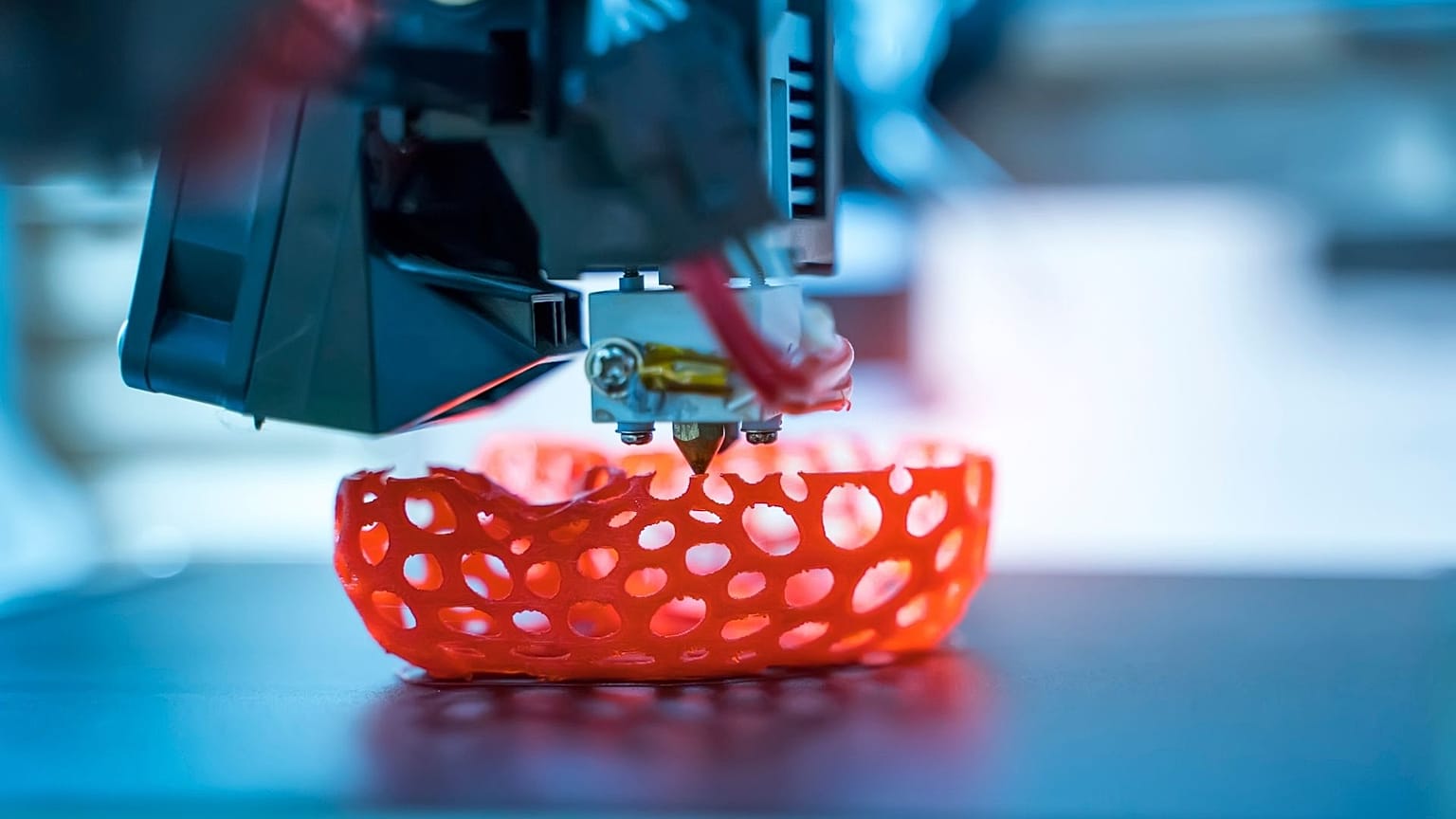

Innovative technology has been disrupting the sector for years, but it’s never been clearer that digital fabrication will play an enormous role in shifting towards better production processes, materials and inks in future.

Technology like 3D printing has the ability to create something bespoke, and does it sustainably. It can also recycle materials that are more environmentally friendly.

This is undoubtedly where the industry must continue to head towards, if brands are to improve the production and distribution of goods.

The brands ahead of the digital trend

Brands like Uniqlo and Shima Seiki in Japan are using digital fabrication technology to print seamless full garments. Wikifactory is also coming up with easy to fabricate, green materials, whether that’s modular cuttings of samples that allow for minimal cut-offs, sustainable eco-leathers created from waste oranges, or wearable technology accessories.

Fabrics are now being designed openly, without the need for copyrights or patents and so the time-to-market is massively accelerated. At Wikifactory, we have a project like this called ‘Resilience’, which is a completely customisable 3D-printed garment at a low cost, where you don’t need to sew a single thread to make and tailor a garment to fit.

We’ve also got a project called aNotherShoe, which is a downloadable design for a pair of loafers without the need for expensive lasts or outsourced manufacturing.

But what I find interesting is the critique of churn and change in fashion. I think the constant innovation in style is an example of creativity, art and culture.

What we need to do now is not reduce creativity, but make fashion more sustainable.

Why innovation and sustainability go hand in hand

Sustainability is not just rising in popularity amongst founders and startups either. Some of the big sports brands, including Adidas, Puma, as well as Brazilian shoe brands Veja and Cariuma, or ON (in collaboration with Roger Federer), are coming up with amazing new material technologies for breathable but synthetic and sustainable leathers.

Adidas’ new Stan Smith Mylo trainers made from mushroom leather raise awareness around plant-based leathers, for example. On the higher end of the spectrum, the fashion industry is signing pledges against using fur, which I hope will have a better impact than similar campaigns did in the 90s.

Meanwhile, Stella McCartney’s sportswear ranges are ground-breaking for using recycled marine plastics. In the bridal industry, worth 14.7 billion to the UK economy, thousands of tonnes of fabric and plastic waste is generated each year.

In New York alone 40,000 tonnes of material waste from the bridal wear industry ends up in landfill.

As a response, the New York based, young couture brand Leanne Marshall has developed a line of dresses made from fragments of other gowns to create a couture range that is sustainable and ethical while still being hand-crafted.

We’re ultimately working towards building an environment where not building ethics into your business model from the inside out is no longer an option.

With more stories emerging about poor working conditions, alongside the greater demand for sustainable fashion, brands - big and small - need to have more of an environmental model to attract and retain their customers. Perhaps it even offers us hope to reinstate fashion, not just as a fad that changes with the seasons, but as an appreciated art form.