16th-century Chinese potters in Jingdezhen made the finest porcelain, a magical material never seen before. Only they knew the production process - a closely guarded secret. But over time Dutch potters began crafting their own precious blue and white ceramics.

When porcelain arrived in Europe from China in the 16th Century it caused a sensation.

ADVERTISEMENT

ADVERTISEMENT

ADVERTISEMENT

ADVERTISEMENT

Potters in Jingdezhen had made a magical material never seen before. Only they knew the production process which was a closely guarded secret. But Dutch potters began crafting their own highly-prized blue and white ceramics.

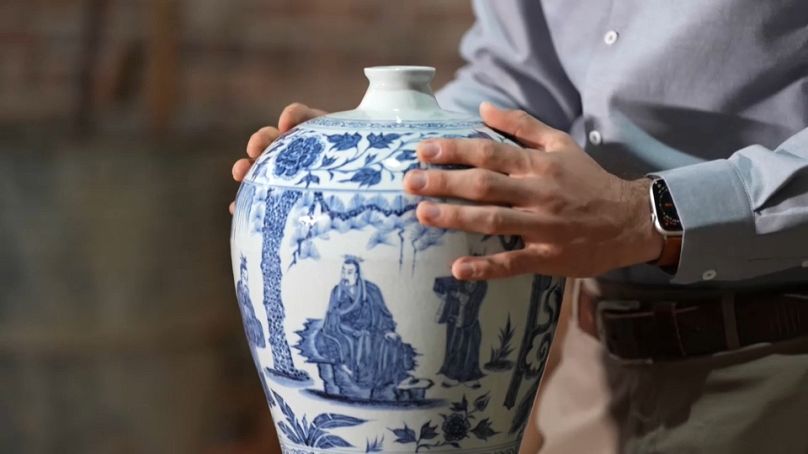

Famous blue and white Qinghuaci porcelain from Jingdezhen in China

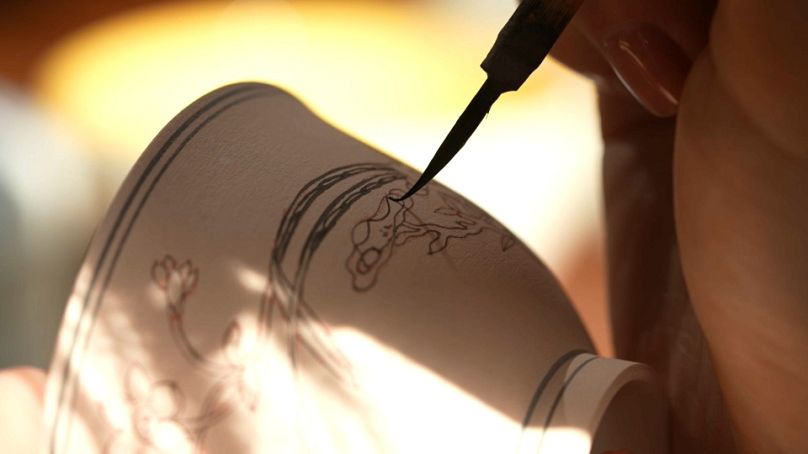

Making Qinghuaci porcelain is a complicated process that involves seventy-two steps. The step called trimming involves removing any excess clay and the thickness has to be very precise, nothing greater than a tenth of a millimetre is permitted. It is an extremely delicate process requiring very skilled craftsmen.

When it comes to glazing, the vessel is immersed quite slowly, although it’s removed surprisingly quickly. The speed is dictated by the object’s shape and the craftsman relies on experience to determine this.

A distinctive feature of blue-and-white porcelain is its elegant underglaze. The design incorporates some of the traditional Chinese ink-and-wash painting techniques, such as fading and tapering. Everything painted on the surface has unique symbolism, usually associated with some form of blessing.

“To produce creative works, you need to get out and discover and appreciate the beauty of life." Explains Chen Yu, Jingdezhen Porcelain Hand Painter. "Without such input, there can be no output. Besides, artistic expression is a highly personal thing – a manifestation of one’s tastes and one’s understanding of life.”

Royal Delft porcelain in the Netherlands

For around four hundred years the Dutch city of Delft has been doing wonderous things with clay.

Delftware designs initially imitated Chinese ceramics, but soon the potters started making their own blue and white ceramics and over time decorative scenes became more Dutch. Mills, ships, and the city of Delft became very popular.

At one point in history, there were about 34 factories in Delft, but today, Royal Delft is the only factory left in the city.

“In Europe, we could not make porcelain." Explains Co van Nieuwenhuijzen, Manager of the Royal Delft Museum. "So in Delft, they started to mix the clay in a different way. They were able to make it thinner. The result looked a lot like Chinese porcelain. That's why people call it Dutch or Delft porcelain, but in fact, it's earthenware. The decorations were very refined and the colour blue was new.”

The Proud Mary is one of the most famous pieces of porcelain made at the Royal Delft factory. The finest ceramics produced today are still painted by hand, which is a highly skilled job that takes around a decade or so to master.

The process uses a special paint containing cobalt. It’s then glazed and fired, during which a magical transformation takes place as a chemical reaction turns the black paint into the iconic blue. Today genuine Delft can fetch a small fortune and each piece is unique.

The critical kiln process in the production of Jingdezhen porcelain

The success or failure of all the work done in Jingdezhen depends on the expertise of the craftsmen supervising the kiln. Years of experience guide them so that they add the wood at just the right time and in the right quantities.

They do this day and night, non-stop, for several days. Since the heat inside the kiln isn’t dispersed evenly, different types of pottery are put in different places inside, according to the amount of heat they require. For example, blue-and-white porcelain needs the hottest place, closest to the kiln’s door.

To achieve the best, most glossy effect pinewood is burned in the kiln. This is because, at a temperature of 1300 degrees, it emits oil.

When it comes into contact with the glaze on a vessel, the pine oil creates a rich, lustrous, polished-looking surface.