Extrusion - the machine process that helps turn bioplastic and recycled food waste into the materials for engineering, including 3D-printed car parts and other components

A mechanical process called "extrusion" helps to turn bioplastics and natural materials recycled from food waste into a thread that can be later used to 3D-print car parts and other industrial components - an innovation unimaginable just a few years ago.

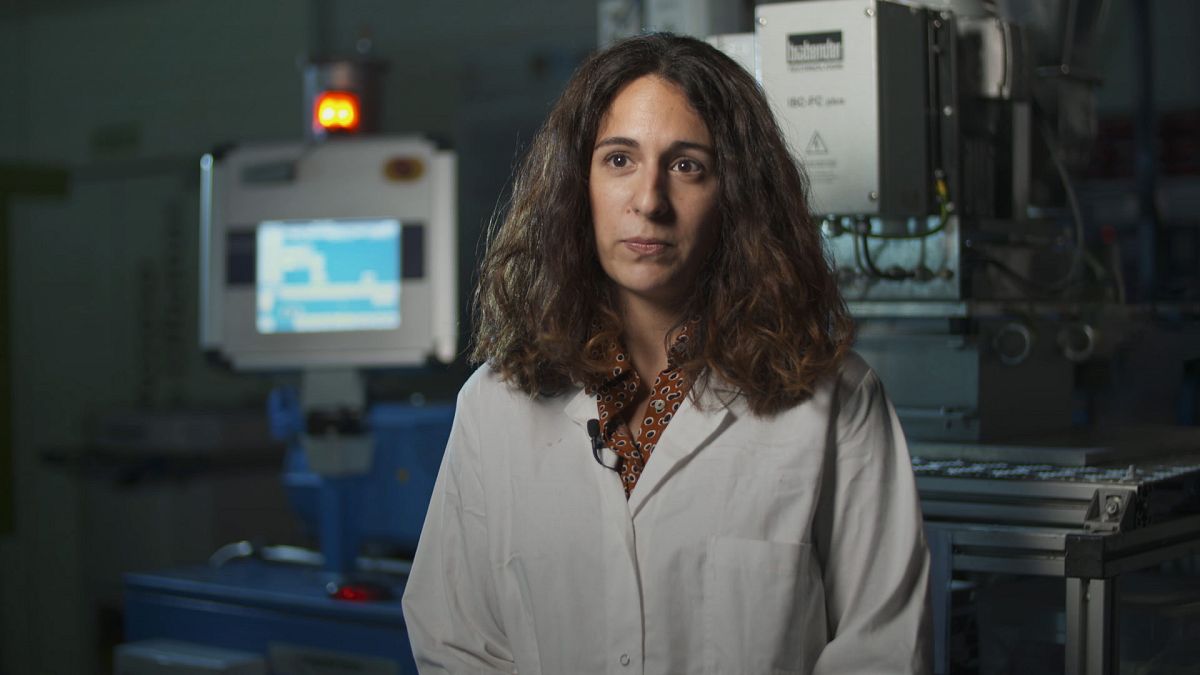

Lidia Garcia Quiles, an industrial engineer at Aitiip Technology Centre which is involved in the BARBARA Project, explains how it works:

"When we need to create a new material, or to improve the specific properties of any given component, or when we need to add substances to create new mixtures, we turn to a machine called the Plastic Extruder.

"Here we mix all the bioplastics and then we melt them. Then we add the materials that will give colour, fragance or antibacterial properties.

"Bioplastics and additives are mixed inside the machine´'s tumbler - a kind of small chamber where all materials are melted and blended.

"At the end, we’ve created a thread that is then washed with water so that it solidifies; we can then cut it down into small pieces: the pellets.

"Once we have these granules, we come to a second stage in the process: the winding. With this procedure, we are able to create another thread but with the specific, pre-determined properties that we are looking for: dimensions, resilience, tolerance to binding, suitable for its later use in 3D printing".