US tech giant Intel is planning further investment in European semiconductor facilities as part of its expansion in the region.

A planned chip fabrication complex in Germany has been dubbed ‘Silicon Junction’ and will comprise leading-edge technology while meeting the most demanding environmental standards.

In combination with the company’s existing and recently expanded semiconductor manufacturing site in Ireland and a planned assembly and test site in Poland, this move marks a significant step towards Intel’s goal to create a sustainable, resilient, geographically balanced semiconductor manufacturing value chain.

Navigating the global chip bottleneck

Intel’s plans for major expansion are, in part, a response to the recent global chip shortage brought about by a perfect storm of increased demand and the COVID-19 pandemic. Disruption has occurred in almost every sector, affecting supply (most notably in the car-manufacturing industry) and cost – many consumer electronics, such as smartphones and laptops, saw price rises as a result.

“The biggest learning is that this shortage solidified the need to diversify the global supply chain to ensure a more balanced and sustainable future for semiconductors,” explains Dermot Hargaden, VP of the sales and marketing group at Intel, and general manager for the Europe, the Middle East and Africa (EMEA) region. “At present, 80 per cent of current semiconductor-manufacturing capacity resides in one geographic region, which creates a reliance on one area of the world to meet global demand.”

The European Commission is addressing this issue via the European Chips Act (ECA), which encourages and invests in semiconductor research and production in Europe. The EU’s goal is to double its global market share in the sector to 20 per cent by 2030 as well as ensuring a secure and resilient production ecosystem.

“A key pillar of the European Chips Act focuses on strengthening the talent pipeline to support the emergence of a skilled workforce that can help the EU achieve its ambitious goals,” says Hargaden.

Intel is investing heavily in this area as a part of our 2030 RISE (Responsible, Inclusive, Sustainable, Enabling) commitment to create thousands of jobs in the region across the entire supply chain lifecycle.”

Strengthening chip-making ecosystems in Europe

Intel’s own commitments and goals run in tandem with those of the EU, and the European expansion is critical to the next phase of company growth, in which Intel plans to create an end-to-end semiconductor value chain, from wafers to complete packaged products, in the region.

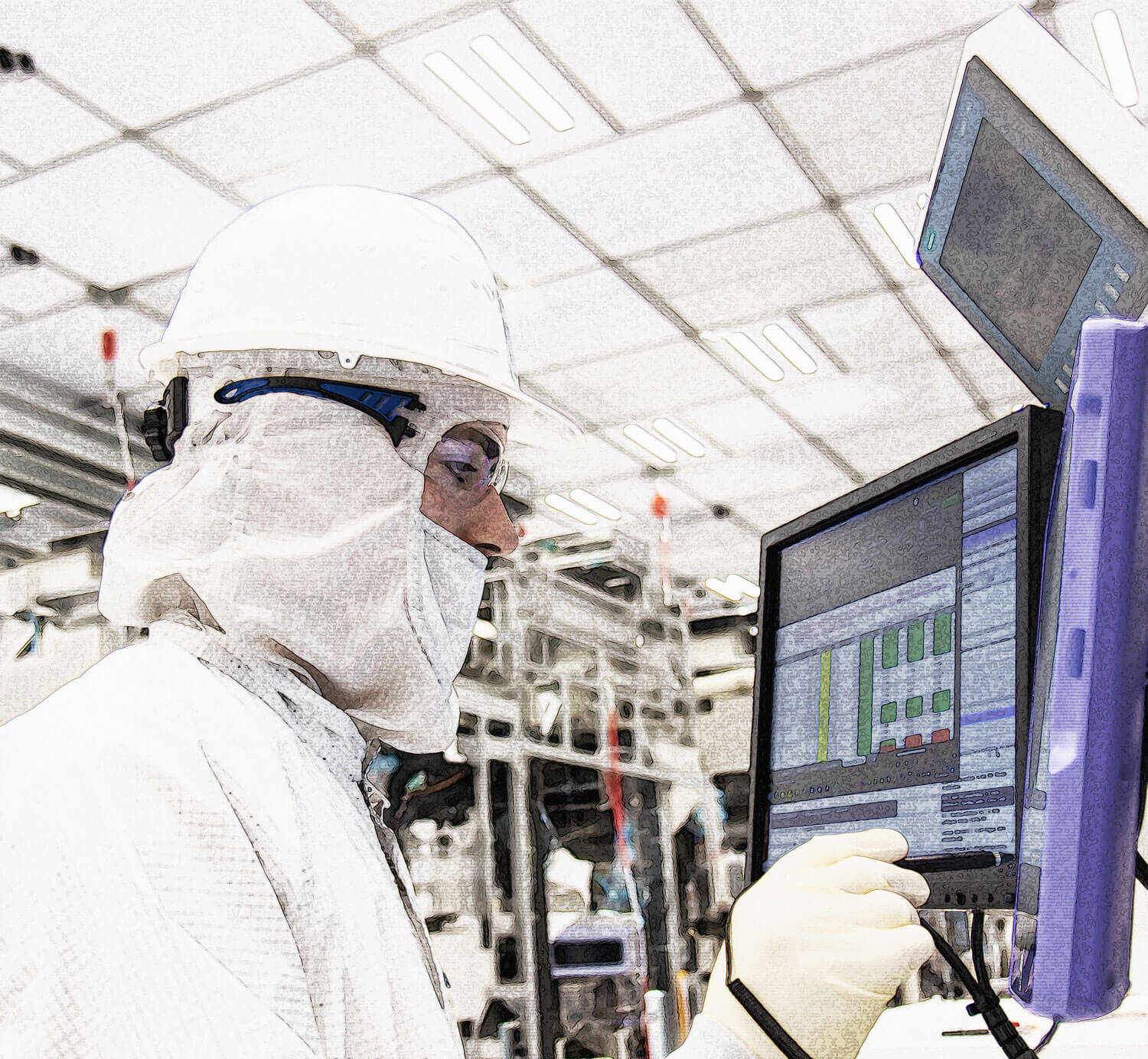

Intel’s existing fabrication plant (known as a ‘fab’) in Ireland, together with the planned facilities in Germany and the assembly and test facility in Poland, form an important part of a strategy to diversify the supply chain, and technological innovations are causing a seismic shift in production efficiency.

We recently reached an exciting milestone at our Fab 34 facility in Ireland,” says Hargaden,

“bringing our first use of extreme ultraviolet lithography [EUV] technology in high-volume manufacturing [HVM] and the first use of EUV in HVM in Europe. The arrival of this technology is critical for ushering in the future of our innovative technology.”

As a major IDM (integrated device manufacturer, which has the means to handle all aspects of production, from design to manufacture), Intel is in a prime position to lead technology and product development across the industry.

Investing in the environment, investing in people

The Fab 34 campus is committed to a series of sustainability objectives. Intel’s Ireland Climate Action Plan was launched with the goal of achieving 100 per cent renewable electricity, zero waste to landfills and net positive water by 2030. As of 2023, 88 per cent of the water used is being returned to the River Liffey and only 0.6 per cent of the annual waste goes to landfill.

The Silicon Junction in Germany is being developed with the same sustainability goals, and in line with green building principles. Looking further ahead, Intel aims for net zero scope 1 (direct) and scope 2 (indirect, from purchased power) greenhouse gas emissions across their global operations by 2040, and net zero upstream scope 3 (greenhouse gas emissions produced externally, such as those generated by suppliers) by 2050 1.

Job creation, too, is at the heart of Intel’s expansion strategy. The Silicon Junction site will require 7,000 construction workers, followed by around 3,000 permanent posts in high tech.

Talent is the backbone of the semiconductor supply chain and essential for meeting near-term and long-term demand,” says Dermot Hargaden.

“It’s also a personal commitment in my role at Intel to upskill the next generation of tech talent across the region.”

Intel’s investment in STEM education across EMEA should ensure a robust supply of skilled workers, while the company’s Skills for Innovation Initiative empowers educators across the region in digital learning and skill-building. Hargaden also emphasises the importance of upskilling existing employees, which he describes as a means of “tapping into the diverse perspectives and ideas that will drive forward the region’s future.”

Building the Intel of the future

Hargaden acknowledges what he describes as macroeconomic headwinds, and emphasises the focus on managing what is currently within Intel’s control, but is optimistic about the future; not just in terms of company growth but in benefits for the wider community.

The shockwaves from the recent semiconductor shortages will continue to be felt for some time, stimulating investment efforts in future-proofing. Intel’s strategy lies in planning for a future with a rosier economic outlook, a future with unfathomable levels of digitisation.

This will involve the investment of tens of billions of dollars and the creation of thousands of new jobs. With the addition of these new sites, and an ongoing commitment to training and talent creation, the European semiconductor manufacturing value chain will play a significant role in meeting the demands of tomorrow’s consumers.

“By planning our future footprint today,” says Hargaden, “we will be that much further ahead when the economy roars back.”

1 Intel’s absolute Scope 1 and 2 GHGs in CY 2022 decreased 4% on an absolute basis vs. a 2019 baseline of 1.61 million metric tons of carbon dioxide equivalent. More information about Intel’s net-zero goals and progress towards those goals is available in its 2022 -23 Corporate Responsibility report (p.71 – 72) and Climate Transition Action Plan (p.7).

Statements in this document that refer to future plans or expectations are forward-looking statements. These statements are based on current expectations and involve many risks and uncertainties that could cause actual results to differ materially from those expressed or implied in such statements. For more information on the factors that could cause actual results to differ materially, see our most recent earnings release and SEC filings at www.intc.com.

Intel technologies may require enabled hardware, software or service activation.

No product or component can be absolutely secure.

Your costs and results may vary.

© Intel Corporation. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Other names and brands may be claimed as the property of others.