As the energy crisis rages on around the world, coal mining continues to be an integral part of the global commodity landscape – with Huawei’s innovative designs set to revolutionise the industry.

This month, Huawei celebrated one year of its intelligent mining solution MineHarmony OS and announced that the operating system has now entered the stage of large-scale commercial use, as 5G and AI break ground on a new era for the industry.

A joint innovation with China Energy Investment Corporation, MineHarmony OS is designed to improve productivity, sustainability and safety by remotely operating mining technology above ground.

Speaking at Huawei Connect 2022, Ken Hu, Rotating Chairman of Huawei, emphasised the company's dedication to working with partners to help industry customers choose the right technology for their needs – and make the most of it.

"To provide our customers with scenario-based solutions that truly meet their needs, we have to work side-by-side to truly understand the challenges in their industry," Hu says.

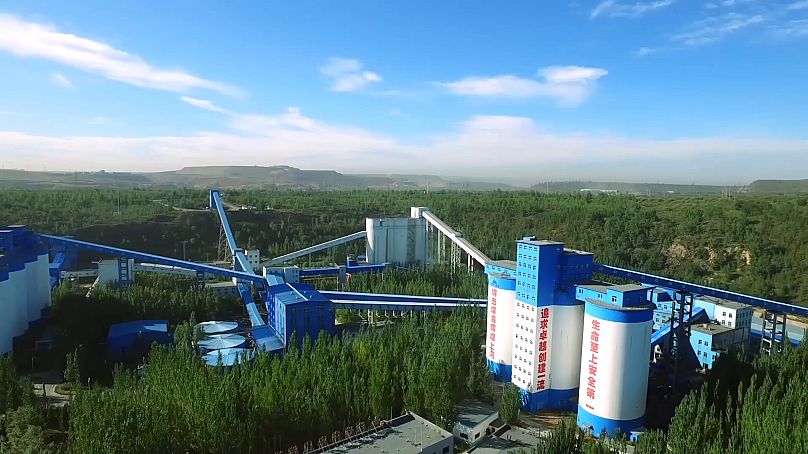

In the last 12 months alone, the system has been deployed on 3,300 sets of equipment in 12 mines and one coal washery. This includes the entire Wulanmulun Mine in Inner Mongolia, where significant progress has been made in connectivity, interface and data access.

The operating system itself covers a multitude of innovative scenarios, including smart control of equipment, an auto patrol of fixed sites and online upgrade of equipment, the time of which has been significantly slashed from one day to just four minutes.

But what does the new technology mean for day-to-day operations?

Intelligent mining in action

With complex and dangerous conditions facing the mining industry, remotely controlling operations is vital, significantly reducing the number of underground personnel and improving safety and efficiency.

But clear and real-time video of the mechanised mining face has always proved challenging – until now.

Whereas the cameras in traditional mines can be affected by dust and faulty optical fibres, Huawei’s 5G networks and the reversed uplink-downlink timeslot configuration technology support wireless backhaul of HD videos with hundreds of channels in real-time.

Using AI technology and a video stitching algorithm, separate images are combined into a panoramic one, working alongside a dust-filtering algorithm to allow maximum visibility around shearers.

Tunnelling is another issue facing the industry and is considered the most difficult and dangerous of all coal mine operations, accounting for more than 40 per cent of all accidents.

More than half of these are caused by human error, with underground operational safety relying on manual supervision.

To address this, Huawei employed 5G and AI algorithms to support tunnelling supervision, detecting violations and quality issues before generating alarms and making rectifications.

The 5G also captures real-time video of the conveyor belts, with AI algorithms accurately identifying anomalies, ensuring the belt runs smoothly.

This replaces manual detection with 24/7 intelligent monitoring and cuts underground inspection personnel by 20 per cent.

MineHarmony OS: Allowing humans and machines to communicate

Underground mining production involves more than 1,000 types of devices, almost half of which are offline and beyond remote control. These devices use more than 10 types of operating systems, 500 types of interface protocols and various data formats – all operating in isolation.

MineHarmony OS operates on industrial IoT (Internet of Things) technology, which facilitates communication between a collective network of devices and the cloud, as well as between the devices themselves.

This effectively allows various machines to speak the same language, providing one set of protocols for data sharing between devices, and enabling human-to-machine and machine-to-machine connectivity.

Using MineHarmony OS, workers can connect their smartphones to mining equipment for visual data display and complete mining operations as easily as sending a text.

And, as well as conducting unattended inspections, miners can also intelligently conduct tasks in real-time, including scheduling evacuations when detecting a gas overflow.

The result is a mining industrial internet platform that runs on unified standards and united frameworks, forging a new modality for mine companies.

And, according to Huawei, future research will allow the experience of experts to be converted into AI algorithms, meaning the industry’s brightest minds can instruct operations anytime, anywhere, for improved practices worldwide.