Robots will build everything: our clothes, our food... but they will start by constructing our homes. This is Tesla veteran Russell Varone's wildest prediction.

He's already providing a glimpse into this future. Varone is the co-founder and CTO of Diamond Age, a US-based company that has successfully constructed 25 houses using 3D printing and robotic technology.

Varone quotes Elon Musk to communicate his vision: “Physics is the law. Everything else is a recommendation. So we abide by that."

My Wildest Prediction is a podcast series from Euronews Business where we dare to imagine the future with business and tech visionaries. In this fifth episode, Tom Goodwin talks with Russell Varone, CTO of Diamond Age, about the future of construction.

What house-building robots look like

In the 2004 science fiction film 'I, Robot', we can see glimpses of a highly automated and futuristic city where robots play a vital role in building and maintaining the infrastructure of society.

The androids are designed with a humanoid appearance. This is not how the robots from the construction company Diamond Age look though, and it's probably not how the future of construction will look either.

They don't have legs, arms, and, of course, they don't have mouths or eyes. They're far from looking humanlike, but that's not the goal.

Russell Varone compares them to a candy crane.

The original candy crane model consists of a transparent or partially transparent rectangular or square compartment containing sweets or toys. Above this compartment is the mechanical claw mechanism, attached to a movable arm.

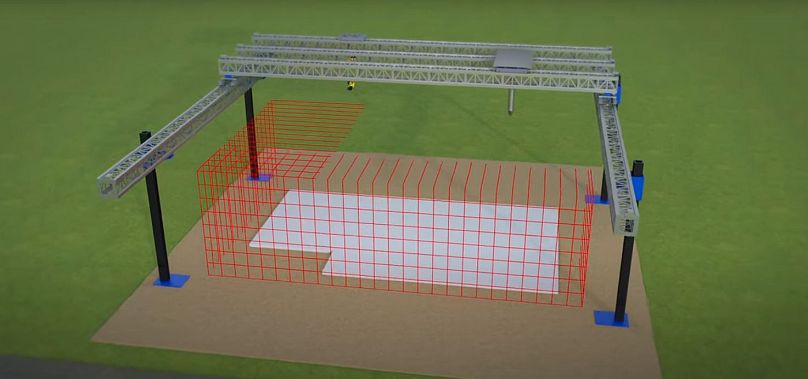

Now imagine a supersized candy crane about 1560 metres wide, 30 metres long, and seven metres high. "It looks like what would unload containers at a port, a big superstructure that we actually have two robots that carry tools around," says Varone.

The robotic arms are very specifically designed to carry big heavy tools, such as concrete printing tools, lift roof structures, and big heavy sheets of stone.

This is how the future of construction actually looks, according to Diamond Age. "We built a system that uses existing materials, concrete, stucco, paint insulation, and builds it in a different way, like you would inside a factory."

Varone then compares the process to the one used for assembling a dollhouse.

First, someone builds the foundation for them. Then, they scan and print the walls layer by layer, adding details like electrical outlets and conduits as the walls grow.

By the time they reach the top, insulation, and channels for plumbing and electrics, are already in place. Finally, they finish by spraying stucco on the outside or applying waterproofing on the inside.

Diamond Age has built 25 houses in the US using this process. The company's long-term goal is to automate 100% of the process.

"We got inspired by one of the leaders in the field on 3D printing, and we said it's a big, expensive machine, and it's hard to set up. Why just do walls? Why not do everything?" says Varone.

"And I've spent 30 years in factories, so I decided I could build a factory outside with a team of people."

An industry resistant to changes

Think of three things we do every day that seemed like science fiction only 20 years ago: paying with our mobile phones, setting a touchscreen GPS in our cars, or having work meetings on video calls with people from around the world.

You probably wouldn't think of construction, which has resisted significant evolution. Workers continue heavy lifting and pounding hammers regardless of the rain, cold, or heat, creating a hazardous work environment.

Why is the biggest industry in the world, worth more than $14 trillion, lagging behind? According to Varone, it's because "right now, good enough is good enough. There's no external influence for people to say, go build it differently."

While Diamond Age is only in the early stages of transitioning to the future of construction, 17 families are already living in their robot-built houses.

"I see them every weekend when I'm at the job site now and shake hands over fences. You get chills because putting people in a home is nothing more satisfying than that," says Russell Varone.

He adds, "You know, Marc Andreessen's famous quote is that software is going to eat the world. I believe robots will build the world."