Euronews takes you on a 360 visit to a mobile phone test lab

As soon as a new phone hits the stands, social media is swarmed with videos of bloggers destroying their brand-new devices, testing its limits to the amusement — and shock — of many.

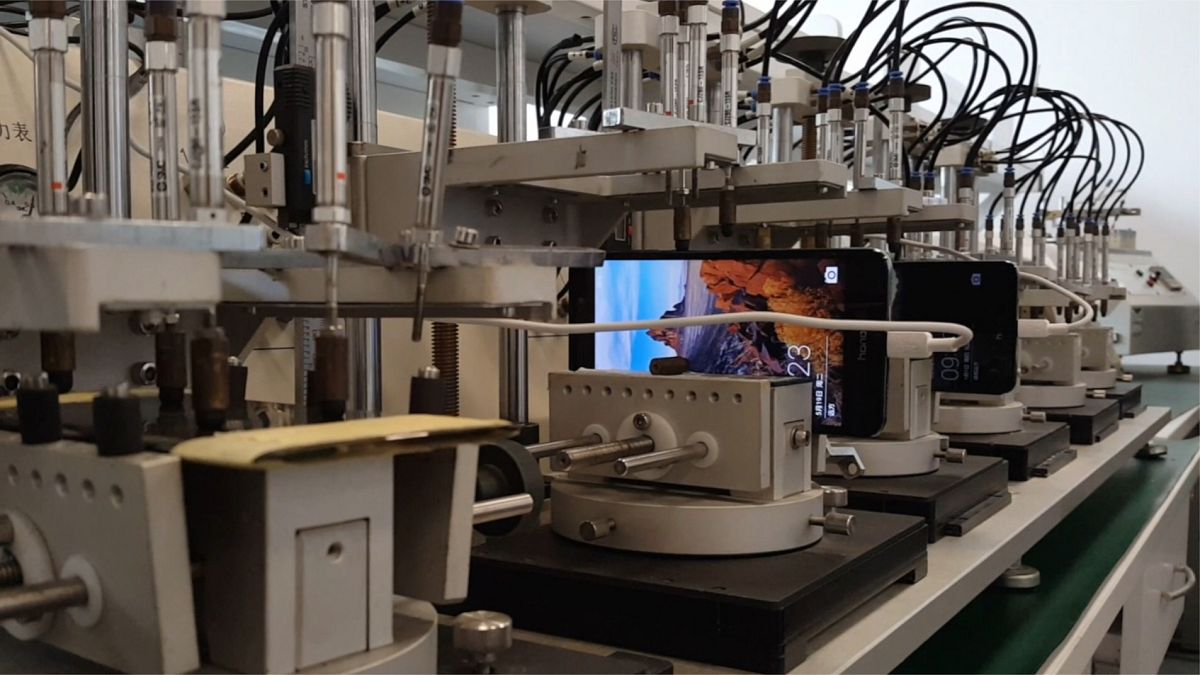

However, long before release, mobile companies put the phones through stress tests themselves.

These tests require much more precision than those shown on YouTube, with the ultimate goal being to determine how certain conditions affect the way the device functions or looks.

Euronews has visited a Huawei test lab in China and brings to you the visit in 360 degrees. The Chinese tech giant’s lab featured is located in Shenzhen, also known as the Chinese Silicon Valley.

Here devices undergo many months of what are known as reliability tests, which puts phones on the brink of endurance. Tests can be focused on environmental or mechanical damaged.

As the name suggests, environmental reliability tests are procedures through which devices are exposed to extreme conditions in terms of temperature, humidity, pressure and solar radiation, for example. The devices are placed inside large machines called test chambers to undergo environmental stress.

Thermal shock chambers expose devices from a temperature as high as 70C to as low as -40C in a matter of minutes, the aim being to see how the phone will respond to drastic changes in temperature. This is particularly important when during the summer, a mobile phone user takes the phone from the beach straight into an area with air-conditioning or, in winter, when phones are transported from very cold outdoor conditions to an indoor area with artificial heating.

On the other hand, mechanical tests have more to do with the physical impact phones face in everyday life.

Drop tests give technicians an accurate idea of how phones hold out as it is dropped in different ways.

A rotating structure for example, constantly tumbles the phone from a height of one metre as it spins around. This mimics a phone being accidentally dropped as the person is walking or running. Another machine helps to evaluate what happens when the phone is dropped forcefully onto hard ground. The phone is propelled towards the floor many times and at different angles.

Further tests, known as “soft-pressure tests”, reenact what would happen if someone put the phone in the back pockets of their trousers and sat on top of the device. The pink cylindrical structure shown in the video applies a pressure of 25 kilograms onto the mobile phone. This pressure needs to be applied 2000 times for the phone to be approved.

Another test applies pressure on the touchscreen, volume and power buttons of the phone, as if someone was pressing them. The buttons are pressed a million times to pass this evaluation.

Cables and charging kits are also tested under mechanical stress in this facility. When plugging a USB charging cable, for example, mobile phone users sometimes try to force the wrong side of the USB port. For this reason, technicians in this facility test the USB port being plugged in the correct manner but also look into what happens when someone forcefully tries to connect the USB on its wrong side, or at a wrong angle.

Adding to his, cable strength and flexibility are also tested. During this evaluation, cables are connected and then constantly twisted around while bearing a weight of 200 grams to see if it will still function.

With all of the stress tests outlined, one may come to the realisation that their phone is much sturdier than they initially thought. But remember, although it might be tempting, don’t try any of these at home.